If you’re looking for the best server rack grounding kits for 2026, I recommend considering options like the MWRF ESD Mat Kit, copper bus bar kits, and Tripp Lite grounding panels. These kits offer quality materials, easy installation, and reliable safety standards. Ensuring compatibility with your rack and certifying compliance is key. If you want to find out which specific kits stand out and how to pick the right one, just continue exploring further.

Key Takeaways

- Select grounding kits with high-quality copper or aluminum materials for optimal electrical conductivity and static protection.

- Ensure compatibility with standard 19-inch server racks and proper mounting hardware for secure installation.

- Verify kits meet safety certifications such as UL, ANSI, or IEC to guarantee compliance and safety standards.

- Opt for complete kits that include grounding bars, cables, hardware, and connectors for easy, all-in-one setup.

- Prioritize durable, corrosion-resistant components like tin-plated lugs and sturdy mounting hardware for long-term reliability.

| MWRF ESD Mat Kit with Wrist Strap and Grounding Cord |  | Best Static Discharge Protection | Compatibility: Suitable for electronics assembly environments | Mounting Method: Grounding cord connects to mat and wrist strap | Conductive Material: Nitrile rubber surface resistive material | VIEW LATEST PRICE | See Our Full Breakdown |

| 19-Inch Copper Bus Bar Kit with Grounding Cable |  | Reliable Grounding Solution | Compatibility: Designed for 19-inch data racks, enclosures, cabinets | Mounting Method: Mounting screws included for rack attachment | Conductive Material: C110 copper bus bar | VIEW LATEST PRICE | See Our Full Breakdown |

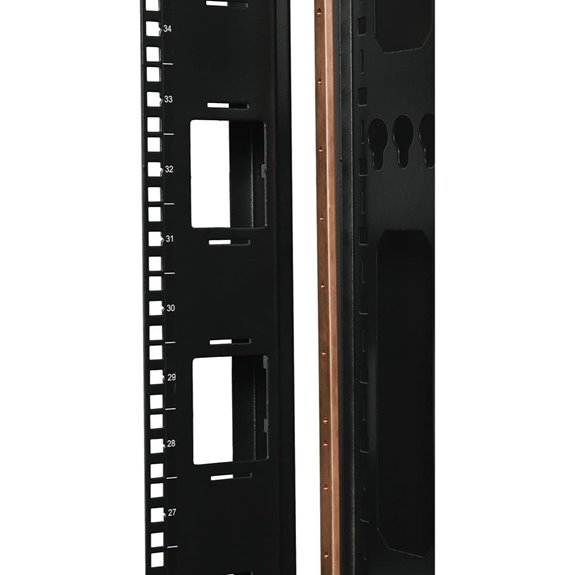

| Tripp Lite 42U Rack Enclosure Grounding Bar |  | Enclosure Compatibility | Compatibility: Attaches to rack enclosures or open frame racks | Mounting Method: Drilled and tapped holes for secure attachment | Conductive Material: Copper bus bar | VIEW LATEST PRICE | See Our Full Breakdown |

| Ground Bar Kit with 10 Terminal Positions |  | Easy Installment | Compatibility: Mounts to 1U of rack space, compatible with standard racks | Mounting Method: Simple installation with included hardware | Conductive Material: Aluminum grounding lugs | VIEW LATEST PRICE | See Our Full Breakdown |

| TRIPP LITE 1U Rack Enclosure Grounding Panel |  | Rack-Mounted Convenience | Compatibility: Fits EIA-standard 19-inch racks | Mounting Method: Mounts within 1U space with hardware included | Conductive Material: Copper grounding bus and wires | VIEW LATEST PRICE | See Our Full Breakdown |

| Panduit RGRKCBNJY Rack Grounding Kit |  | Versatile Grounding Kit | Compatibility: Suitable for 19-inch racks adhering to EIA-310 standards | Mounting Method: Thread-forming screws for secure rack installation | Conductive Material: Metal components (unspecified but compliant) | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

MWRF ESD Mat Kit with Wrist Strap and Grounding Cord

If you’re working in a static-sensitive environment like electronics assembly, the MWRF ESD Mat Kit with Wrist Strap and Grounding Cord is an excellent choice for ensuring safety. It includes everything you need: a 20 x 24-inch nitrile rubber ESD mat, a wrist strap, and a 10-foot grounding cord. The kit is designed to dissipate static charges effectively, protecting your components from damage. Its surface resistivity of 10^9 to 10^10 ohms guarantees reliable static control. Compact and easy to use, this complete set helps create a safe workspace. I recommend it for anyone serious about static discharge prevention in sensitive environments.

- Compatibility:Suitable for electronics assembly environments

- Mounting Method:Grounding cord connects to mat and wrist strap

- Conductive Material:Nitrile rubber surface resistive material

- Grounding Connection:Wrist strap, grounding cord, and mat for static dissipation

- Number of Components:3 components (mat, strap, cord)

- Certification/Standard:Not specified

- Additional Feature:Complete static control set

- Additional Feature:Nitrile rubber surface

- Additional Feature:Safe for electronics assembly

19-Inch Copper Bus Bar Kit with Grounding Cable

The Inch Copper Bus Bar Kit with Grounding Cable stands out as an ideal choice for data center professionals who need a reliable and straightforward grounding solution for 19-inch racks. Made of durable C110 copper, it offers excellent conductivity and longevity. The kit includes a 3/15 x 1.2 x 19-inch copper bus bar, a 4-foot, 10 AWG tinned copper grounding cable, and stainless steel screws for secure installation. It’s UL listed, ensuring safety and quality. You can position it anywhere within your rack, cabinet, or enclosure to meet grounding requirements efficiently. This kit simplifies grounding, helping maintain system safety and compliance effortlessly.

- Compatibility:Designed for 19-inch data racks, enclosures, cabinets

- Mounting Method:Mounting screws included for rack attachment

- Conductive Material:C110 copper bus bar

- Grounding Connection:Copper bus bar with grounding cable

- Number of Components:2 main components (bus bar, grounding cable)

- Certification/Standard:UL listed

- Additional Feature:Made of C110 copper

- Additional Feature:UL listed for safety

- Additional Feature:Includes stainless steel screws

Tripp Lite 42U Rack Enclosure Grounding Bar

For those seeking a reliable grounding solution for large rack systems, the Tripp Lite SRGROUND 42U Rack Enclosure Grounding Bar offers an essential feature: drilled and tapped holes at each U space that simplify the installation of ground wire jumpers. This design makes it straightforward to connect individual equipment pieces directly to the ground, creating a continuous, reliable grounding path. The copper bus bar attaches easily to rack enclosures or open frame racks, ensuring compatibility. Plus, all necessary mounting hardware is included, so installation is quick and hassle-free. This grounding bar enhances safety and system stability, making it an excellent choice for demanding server environments.

- Compatibility:Attaches to rack enclosures or open frame racks

- Mounting Method:Drilled and tapped holes for secure attachment

- Conductive Material:Copper bus bar

- Grounding Connection:Bus bar with ground jumpers

- Number of Components:1 bus bar with hardware

- Certification/Standard:Not specified

- Additional Feature:Attaches to rack cabinets

- Additional Feature:Drilled and tapped holes

- Additional Feature:Facilitates ground wire jumpers

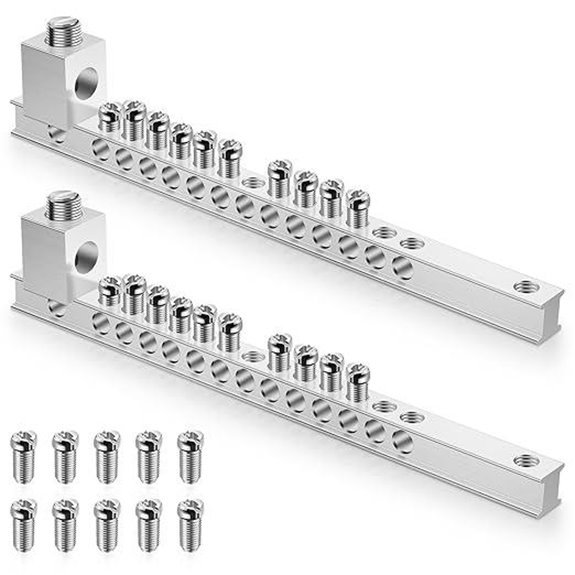

Ground Bar Kit with 10 Terminal Positions

A Ground Bar Kit with 10 Terminal Positions stands out as an excellent choice for professionals managing complex electrical systems. It includes two sets of grounding strips, each with 10 terminal points and #4-2/0 grounding lugs, meeting safety standards. The kit offers easy installation with all necessary components, requiring no special tools or advanced skills. Made from sturdy aluminum, the grounding lugs are durable and reliable for long-term use. The tin-plated surface improves corrosion resistance and conductivity, ensuring a long-lasting connection. It’s perfect for connecting multiple grounding conductors in residential, commercial, or industrial power setups.

- Compatibility:Mounts to 1U of rack space, compatible with standard racks

- Mounting Method:Simple installation with included hardware

- Conductive Material:Aluminum grounding lugs

- Grounding Connection:Grounding lugs connecting multiple conductors

- Number of Components:2 grounding strip kits

- Certification/Standard:Not specified

- Additional Feature:Aluminum grounding lugs

- Additional Feature:Tin-plated for corrosion resistance

- Additional Feature:Suitable for complex wiring

TRIPP LITE 1U Rack Enclosure Grounding Panel

If you’re looking to guarantee reliable grounding in your rack setup, the TRIPP LITE 1U Rack Enclosure Grounding Panel offers a straightforward solution. This panel mounts seamlessly into 1U of space and is compatible with both rack enclosures and open frame racks, fitting standard 19-inch racks. It provides secure ground contact for banana-plug and alligator-clip ESD bands, ensuring proper electrostatic discharge protection. With 48-inch ground wires included, connections are quick and easy. Plus, the panel comes with a 5-year limited warranty, giving you confidence in its durability and performance for your server and network environments.

- Compatibility:Fits EIA-standard 19-inch racks

- Mounting Method:Mounts within 1U space with hardware included

- Conductive Material:Copper grounding bus and wires

- Grounding Connection:Grounding panel with wires and banana connectors

- Number of Components:1 grounding panel with wires

- Certification/Standard:Not specified

- Additional Feature:Mounts in 1U space

- Additional Feature:Includes 48-inch ground wires

- Additional Feature:Ensures proper ESD grounding

Panduit RGRKCBNJY Rack Grounding Kit

The Panduit RGRKCBNJY Rack Grounding Kit stands out as an ideal choice for network professionals seeking a reliable, easy-to-install grounding solution for 19-inch racks. Designed to maintain top-tier network performance and protect equipment, it serves as a solid alternative when RGS rack grounding strips aren’t suitable. The kit includes matched components that simplify installation, with thread-forming screws that eliminate the need to remove paint from racks, ensuring secure connections. Compatible with EIA-310 standards and built to meet US and international safety requirements, this grounding kit enhances system reliability and safety in a variety of environments.

- Compatibility:Suitable for 19-inch racks adhering to EIA-310 standards

- Mounting Method:Thread-forming screws for secure rack installation

- Conductive Material:Metal components (unspecified but compliant)

- Grounding Connection:Grounding kit with screws and connectors

- Number of Components:Complete set with screws and components

- Certification/Standard:Meets US and international grounding standards

- Additional Feature:Thread-forming screws included

- Additional Feature:Compatible with EIA-310 standards

- Additional Feature:Supports reliable network grounding

Factors to Consider When Choosing a Server Rack Grounding Kit

When selecting a server rack grounding kit, I focus on compatibility with my racks to guarantee a proper fit. I also consider the quality of the grounding materials, ease of installation, and whether the kit meets industry standards. Finally, I check the kit’s conductivity and resistance to make sure it provides reliable protection.

Compatibility With Racks

Choosing a grounding kit that fits your server rack properly is essential to guarantee a secure and effective grounding connection. First, verify the kit is compatible with standard 19-inch racks, the most common size in data centers. Confirm that the mounting hardware and dimensions match your specific rack model or enclosure to ensure a snug fit. Additionally, check if the grounding kit is suitable for your rack’s material, whether steel or aluminum, to avoid installation issues. It’s also important that the connection points align with existing rack features like tapped holes or designated grounding areas. Finally, select a kit that supports your rack’s configuration, whether it’s a server cabinet, open frame, or enclosed system, ensuring seamless integration and reliable grounding.

Grounding Material Quality

Selecting the right grounding materials directly impacts the effectiveness and longevity of your server rack’s grounding system. High-quality materials like copper or aluminum ensure superior electrical conductivity and static dissipation. Copper components typically have lower resistivity, making them more dependable for grounding. Additionally, tin-plated surfaces on grounding lugs improve corrosion resistance, which extends the lifespan of connections and maintains performance over time. The durability and purity of the material are vital factors, as they directly influence long-term reliability. Using UL-listed, compliant materials not only guarantees adherence to safety standards but also minimizes the risk of electrical failures. Prioritizing quality in grounding materials ensures your system remains safe, effective, and durable for years to come.

Ease of Installation

To guarantee a smooth and efficient installation process, it’s important to look for server rack grounding kits that feature clearly labeled and color-coded components. This helps prevent mistakes and speeds up setup. Kits that include detailed instructions or thorough guides are also essential, ensuring proper installation without guesswork. Choosing solutions with pre-installed screws and easy-access connection points reduces assembly time and frustration. Modular or plug-and-play designs allow for quick attachment to different rack types, making the process even simpler. Additionally, selecting kits that come with all necessary hardware and connectors means fewer trips to the hardware store or searching for missing pieces. Overall, these features make installing your grounding kit straightforward, saving time and ensuring a secure, reliable setup.

Certification and Standards

When evaluating server rack grounding kits, confirming that they meet industry standards is a key step to ensure safety and reliability. I always check if the kit complies with recognized certifications like UL, ANSI, or IEC, which guarantee the product meets essential safety benchmarks. It’s also important to verify that the components are rated for the typical voltage and current levels in server environments, preventing potential overloads. Certifications confirming adherence to regional electrical codes and regulations further ensure compliance and peace of mind. Additionally, I look for documentation showing compliance with ESD and static discharge standards, protecting sensitive electronics. Durability and corrosion resistance are also critical—materials should meet long-term use standards. Proper certification is essential for safe, reliable, and compliant grounding solutions.

Conductivity and Resistance

Ever wondered why some grounding kits perform better than others? It all comes down to conductivity and resistance. Conductivity measures how well a material transmits electrical current with minimal resistance. The lower the resistance, the more efficiently static charges are dissipated, which is vital for safety. Materials like copper or tinned copper are ideal because they offer high conductivity and low resistance. Resistance is measured in ohms, and a good grounding kit will have very low values, ensuring reliable electrostatic discharge (ESD) protection. Surface resistivity also plays a role, affecting how effectively static charges are released. When choosing a grounding kit, prioritize those with high conductivity and low resistance to guarantee your server rack remains protected and safe against static buildup.

Kit Completeness

Choosing a complete server rack grounding kit is vital for effective grounding and safety. I look for kits that include all necessary components—grounding bars, cables, hardware, grounding lugs, and jumpers—to guarantee thorough coverage. Compatibility with standard 19-inch racks is essential for a proper fit and reliable grounding. Pre-installed screws and connectors make installation easier and faster, saving time and reducing errors. I also check that the kit offers multiple connection points or terminal positions, allowing me to connect various devices within the rack effortlessly. Including all hardware ensures I won’t need to purchase additional parts separately. A well-rounded kit simplifies setup, guarantees proper grounding, and enhances safety across the entire rack, making it a smart investment for reliable electrical protection.

Durability and Longevity

Durability and longevity are crucial factors to contemplate because a grounding kit must withstand environmental conditions and regular use over time. High-quality materials like copper, aluminum, or stainless steel ensure the components resist wear and corrosion. Surface treatments such as tin plating further enhance resistance, extending the lifespan of the grounding system. The thickness and gauge of conductors also matter; thicker gauges typically offer greater durability and can handle more stress. Additionally, sturdy mounting hardware and thoughtful design features secure components firmly, reducing wear from vibrations or movement. Regular maintenance and inspections are essential to catch signs of degradation early, keeping the grounding system effective and reliable for years. Choosing a kit built with these considerations in mind guarantees long-lasting safety for your server rack.

Cost and Budget

When selecting a server rack grounding kit, understanding your budget is essential to finding a cost-effective solution that still meets safety standards. I recommend setting a clear budget range upfront to help narrow your options. Comparing prices across different kits allows you to find a balance between affordability and necessary features. Keep in mind, the lowest price isn’t always the best; consider the long-term value and durability of the kit to ensure it withstands future use. Don’t forget to factor in additional costs like installation tools or professional fees, which can add up. Most importantly, verify that the kit complies with industry safety regulations. Choosing a compliant, durable, and affordable grounding kit saves you money and helps maintain a safe, reliable server environment.

Frequently Asked Questions

How Often Should Server Rack Grounding Kits Be Inspected?

I recommend inspecting your server rack grounding kits at least once every six months to make certain they’re in good condition. Regular checks help catch corrosion, loose connections, or damage early, preventing potential safety hazards or equipment failures. If your environment is particularly harsh or noisy, consider inspecting them more frequently, like quarterly. Staying proactive with inspections keeps your system grounded, safe, and running smoothly.

Are Grounding Kits Compatible With All Server Rack Brands?

Grounding kits are like universal adapters—they’re compatible with many server rack brands, but not all. I always check the specifications before purchasing to guarantee compatibility. Some brands might use unique grounding points or connectors, so I recommend verifying whether the kit matches your rack’s design. This way, you avoid surprises and ensure your setup stays safe and properly grounded, regardless of the brand.

What Safety Certifications Should a Grounding Kit Have?

You should look for grounding kits with safety certifications like UL, ETL, or CSA. These certifications guarantee the kit meets strict safety standards and is reliable. I always check for these marks before purchasing, as they give me confidence that the grounding kit has been tested for safety and performance. Choosing certified products helps protect your equipment and keeps you safe from electrical hazards.

Can Grounding Kits Prevent Electrical Surges?

Yes, grounding kits can help prevent electrical surges by providing a direct path for excess electricity to safely dissipate into the ground. I always make sure my server rack has a proper grounding kit installed because it reduces the risk of damage from power surges and electrical faults. While they don’t stop surges entirely, they substantially minimize the impact, keeping my equipment safer and more reliable.

How Does Improper Grounding Affect Server Performance?

Improper grounding can seriously impact server performance by causing electrical noise, voltage fluctuations, and even equipment damage. When servers aren’t properly grounded, they’re more vulnerable to power surges and static buildup, which can lead to crashes or data loss. I always recommend ensuring proper grounding because it stabilizes power flow, reduces interference, and extends your equipment’s lifespan, keeping your server running smoothly and safely.

Conclusion

Choosing the right grounding kit might seem like a small detail, but it can make a big difference in keeping your setup safe. I’ve found that the best options often come down to what fits your rack and your needs—coincidence or not, the right grounding can prevent surprises down the line. So, take a moment to contemplate these top picks, and you’ll be surprised how much safer and smoother your server experience becomes.